Smooth Overlay Fusing Technology

DuroFlux

DuroFlux overlay plate consists of a mild steel base combined with a fully smooth, wear-resistant coating, presenting a steel overlay sheet of superior quality.

Its outstanding wear and impact performance is enabled by unique chemical composition; computerised welding technologies, and one of the kind micro structure.

We fight wear, throughout

Uniform microstructure and even hardness distribution from top surface down to fusion line* to enable a predictable wear rates.

We fight wear, smoothly

Smooth surface with no weld beads to interrupt material flow or hangup.

-

DuroFlux plates are manufactured using a proprietary process that fuses chromium-rich powder onto a mild steel base plate. Deriving from Japan, our fusing technology has evolved after years of continuous research and innovation to enable a product that achieves smooth surface and wear resistance.

-

The microstructure of DuroFlux Plates are saturated with extremely fine and hard M7C3 chrome carbide that are evenly dispersed throughout the alloy matrix.

-

Mobile Plants: Truck body, Excavator buckets, Digger buckets, Dozer blades, Shovels

Fixed Plants: Transfer Chutes, Discharge Chutes, Surge Hopper, Feed bins, Screens

-

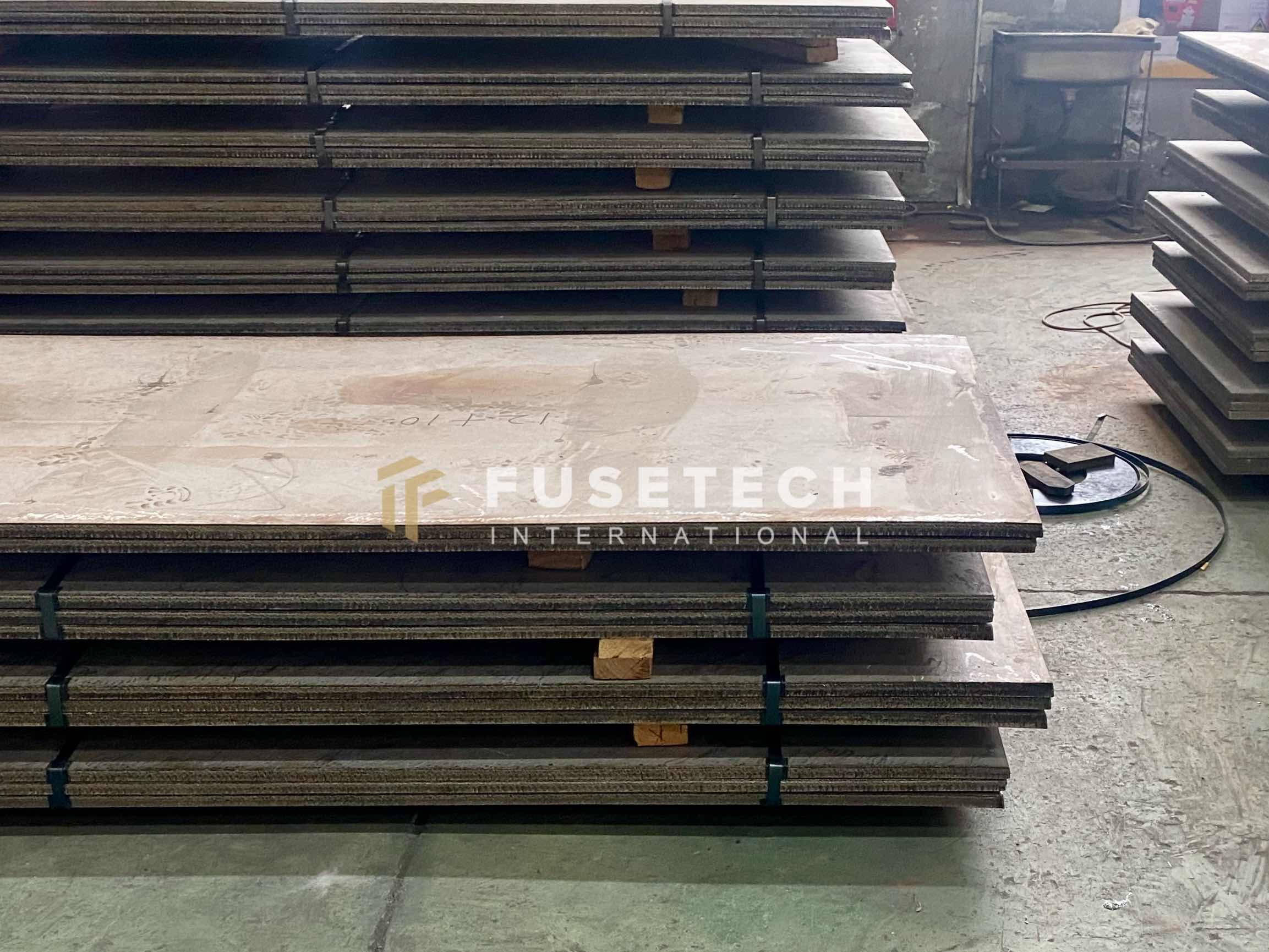

Our standard size is 1000mm x 3000mm;

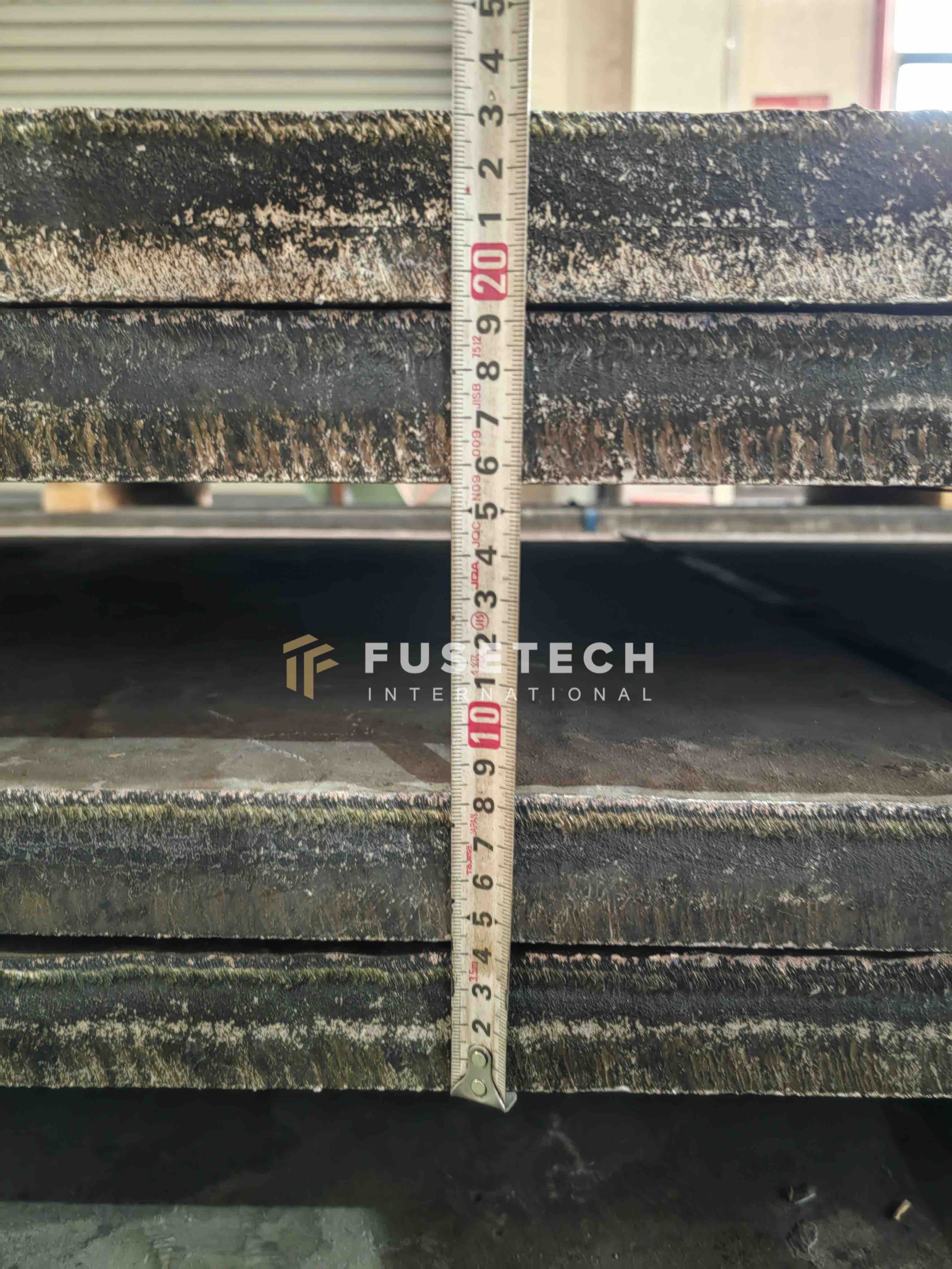

DuroFlux plate range products can be manufactured in different thicknesses;

Alloy depth: 5, 6, 8, 10, 12, 17, 20, 25 mm;

Base metal depth: 5, 6, 8, 10, 12, 13 mm.

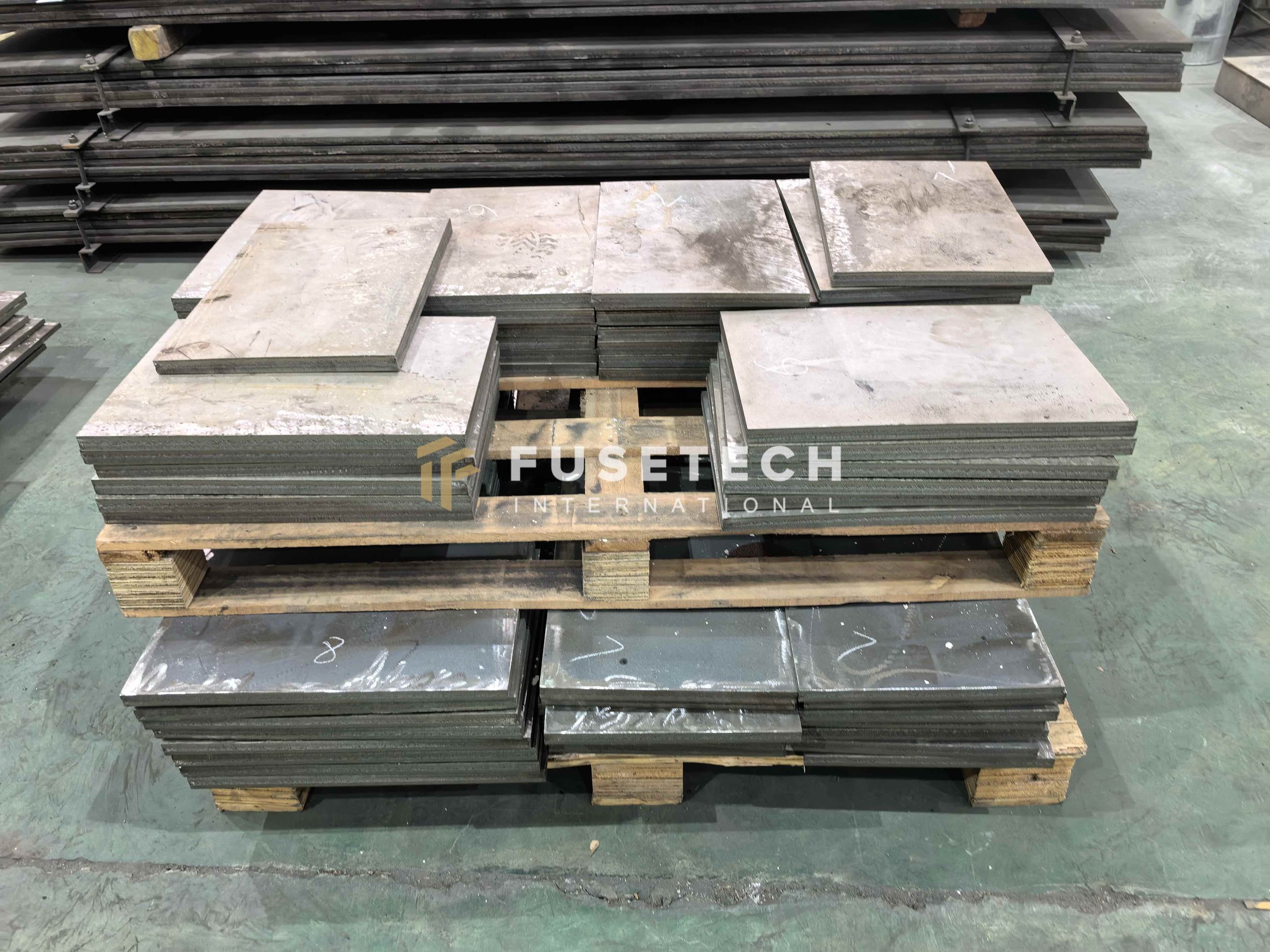

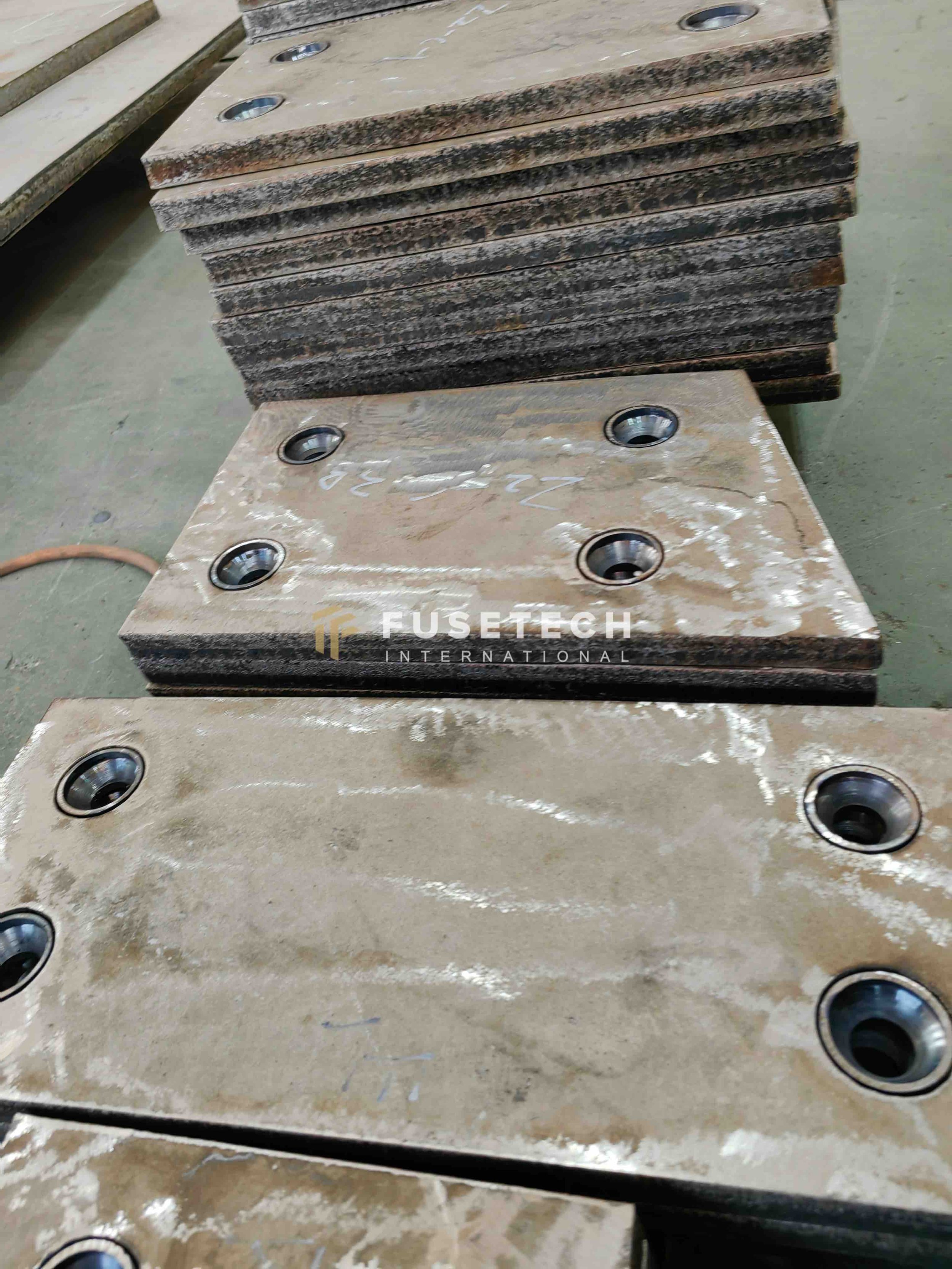

DuroFlux sample

DuroFlux in manufacturing

DuroFlux M30 microstructure

DuroFlux M70 microstructure

Our smooth CCO plates can be cut, rolled, bent, and shaped to your unique requirements and specifications, common techniques for attaching our wear components or overlay plates to your machinery include welding, bolting, and stud welding.